U-shaped flexible straws are drinking straws that bend and have a U-shaped curve for attaching to drink cartons (milk, juice boxes, etc.). They are made of plastic (e.g., polypropylene [PP]) or biodegradable materials (e.g., PLA). The design makes it easy for children and people on the go to access drinks in small packages.

The straws are pre-folded in a “U” shape and are typically heat-sealed or glued to the outside of drink packs. This packaging makes them portable, sanitary, and efficient.

|

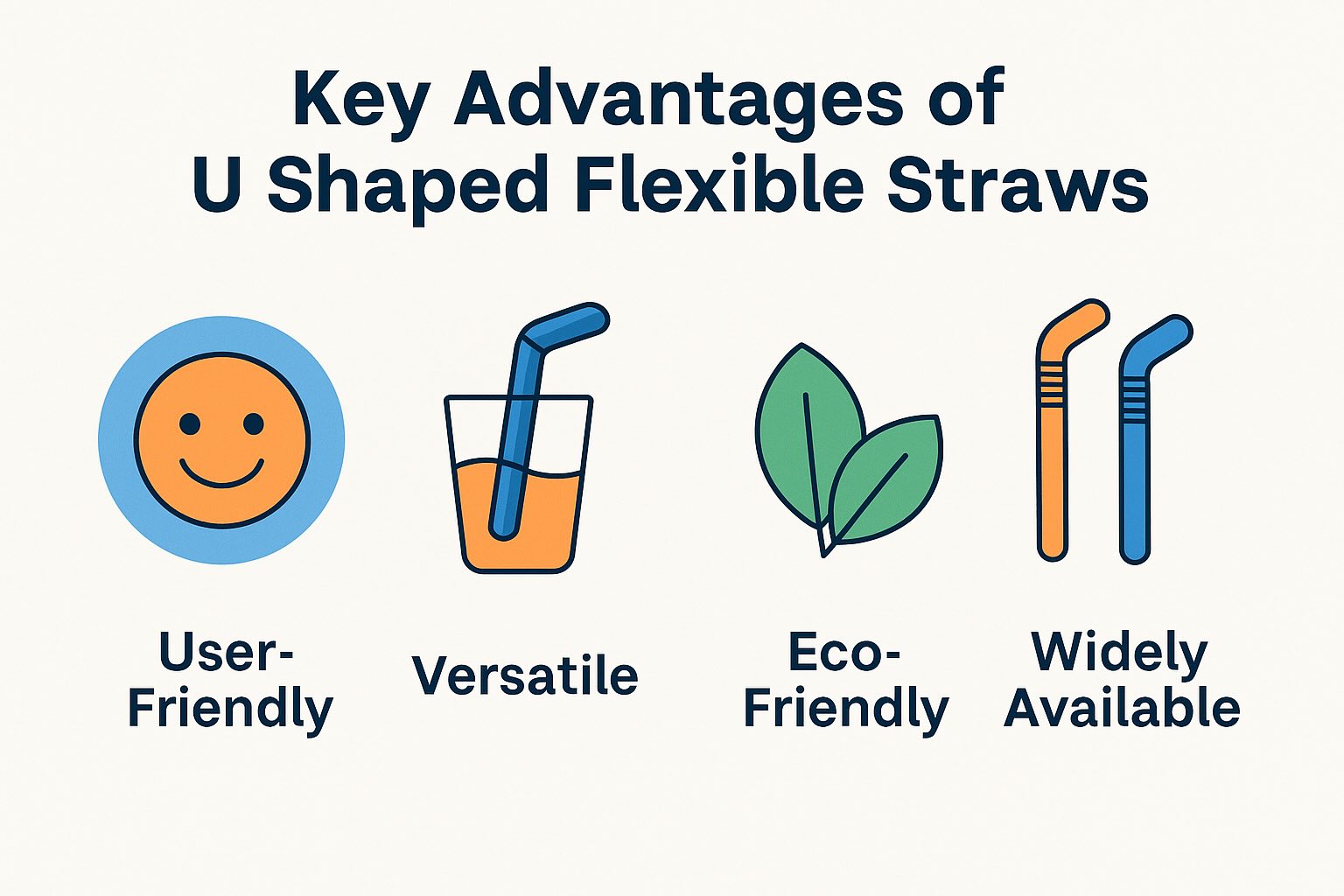

User-Friendly Design: The bendable structure makes drinking easier for children, the elderly, or anyone consuming beverages from small cartons.

Compact Packaging: Their U shape allows for efficient stacking and minimizes packaging space, contributing to cost-effective transportation.

Automation Friendly: These straws are compatible with automated application systems, especially in production lines for drinks packed with Tetra Pak and similar formats.

Customizable: Manufacturers can produce U-shaped straws in various colors, sizes, and packaging styles (individual or chain-linked/strip-packed).

Hygienic: Packaged directly onto the product, reducing contamination and ensuring safety.

|

U-shaped straws can be manufactured using a variety of materials depending on cost, durability, and environmental requirements:

Polypropylene (PP): The most common choice due to its balance of flexibility and food-grade safety.

Polylactic Acid (PLA): A biodegradable, compostable material made from renewable resources like cornstarch. Suitable for eco-conscious markets.

Common ApplicationsU-shaped flexible straws are used in a variety of industries:

|

|

Here’s how U-shaped flexible straws are made:

Depending on your production level and budget, the steps can be fully automated or done semi-automatically.

|

Though there is more concern about single-use plastics, U shaped straws still exist for several reasons:

In markets that value cleanliness, portability, and ease of use, U-shaped straws continue to fill a functional need.

If you're looking to manufacture or source U-shaped straws, consider the following:

Materials supported: Make sure the machines or suppliers support PLA, PP, or your desired material.

Production volume: Choose between semi-auto or fully automated systems based on your capacity needs.

Packaging style: Do you need single straws or continuous strip packing?

After-sales support: For manufacturers, technical assistance and spare parts availability are key.

Looking for high-performance straw bending or Tetrapak straw packing machines? Explore our product line or contact us for a tailored solution.

U-shaped flexible straws continue to offer convenience and versatility in beverage packaging. With the ability to adapt to biodegradable materials and automated production processes, they remain a valuable packaging component. Whether you're a packaging company, beverage brand, or machinery buyer, understanding the structure, production, and benefits of U-shaped straws will help you make better decisions in a competitive market.