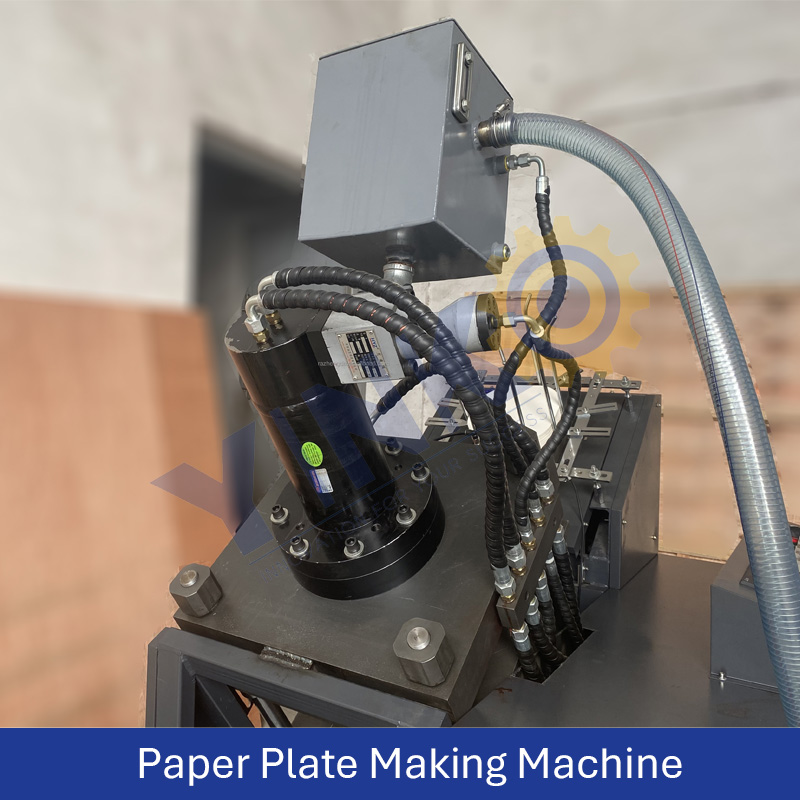

Efficient Single/double-station hydraulic machine for producing large-size and deep-form paper plates, trays, and containers. Supports a wide range of materials and mold shapes with stable performance and high output—ideal for disposable tableware manufacturers.

Modèle Non :

ZPJ-600Nom du produit :

Paper Plate Making MachineTension :

380V 50HZ 3PhaseCapacité de production :

15-50pcs/minUsage :

paper plate makingPort d'expédition :

Shanghai,Ningbo,Shenzhen,Délai de mise en œuvre :

35 daysLester :

2800Kg

Struggling with uneven pressure, limited mold compatibility, or slow production in your current paper plate setup?

The ZPJ-600 Double Station Paper Plate Machine is built to solve exactly those problems.

Engineered with a 30-ton hydraulic press and dual working stations, this machine is tailor-made for high-pressure forming of large, deep, and custom-shaped paper plates and trays. Whether you’re producing round banquet plates, rectangular meal containers, or extra-deep dishware, it delivers uniform quality and excellent edge definition — every single time.

Thanks to its automated feeding, dual heating system, and PLC smart control, your operators can enjoy safe, efficient, and hands-free production, even in high-volume scenarios.

This model supports a variety of materials such as PE-coated paper, aluminum foil, and high-GSM cardboard, enabling you to easily adapt to market demands — from eco-conscious biodegradable trays to luxury embossed party plates.

✅ Facing rising labor costs? Let automation reduce your reliance on skilled operators.

✅ Dealing with production inconsistency? Our hydraulic precision eliminates variation.

✅ Need to stand out with custom shapes? The ZPJ-600 supports flexible mold changeovers and deep-draw performance.

Built for durability, scalability, and 24/7 operation, the ZPJ-600 is the ideal choice for manufacturers aiming for premium quality, fast lead time, and competitive pricing in the disposable tableware industry.

Key Features:

🔧 Hydraulic Forming System: 30 tons of pressure for stable shaping

⚙️ Dual-Station Design: Increases output up to 50 pcs/min

🔁 Custom Mold Support: From 3” to 16.5” sizes

🔥 Up-Down Dual Heating: Ensures perfect mold finish

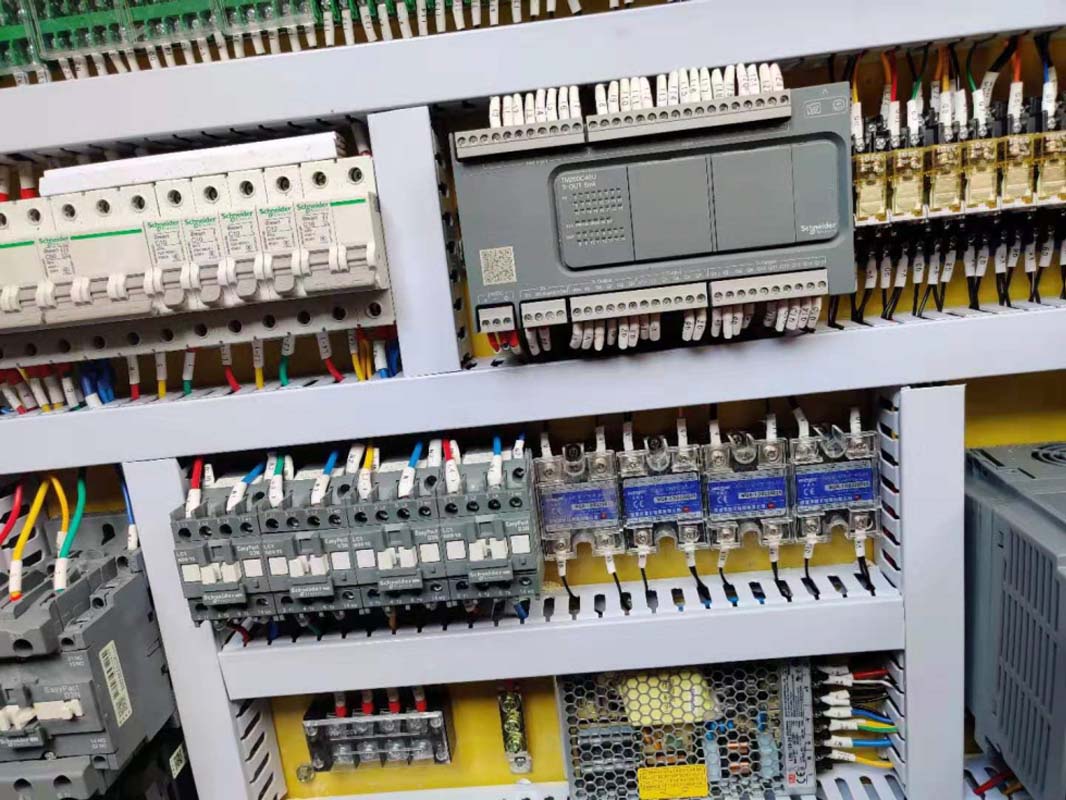

🧠 PLC Control + Safety Sensors: Easy to operate, worker-safe

💡 Heavy Iron Frame Construction: 1500kg real weight, more stable than traditional builds

💯 Energy Efficient: 75% energy saving compared to similar models

|

|

Control Panel, PLC+HMI |

|

Up & down dual heating ensures perfect mold finish |

|

30 tons of pressure for stable shaping |

|

Schneider brand electrical components for reliability |

|

Max cutting paper size |

420*420MM |

|

Size of the plates (trays) |

3—16.5 inches or as ordered, mold changeable |

|

Material |

Original paper, whiteboard, white cardboard, aluminum foil, etc. |

|

Thickness of paper |

160-2500 gsm |

|

Speed |

15-25 pcs/min (1 die), 30-50 pcs/min (2 dies) |

|

Power supply |

380V, 50HZ |

|

Hydraulic pressure |

30T |

|

Total Power |

13.0 kW |

|

Machine weight |

2800 kg |

|

Measure (L*W*H) |

2550*1850*2100mm |

|

Air supply |

0.5 MPa, 0.5 m3/min |

Paper lunch plates & trays

Ice cream or fast food serving dishes

Gold foil decorative plates

Disposable rectangular or round trays

Custom branded event packaging

1. What types of plates can this machine produce?

The ZPJ-600 can produce a wide range of paper products including round plates, square trays, deep containers, and custom-shaped dishes. It is especially suited for large-sized and deep-draw items.

2. What materials are compatible with this machine?

This machine supports PE-coated paper, aluminum foil paper, cardboard, and other food-grade base materials ranging from 250gsm to 450gsm.

3. Is it difficult to change the mold for different plate sizes?

Not at all. The ZPJ-600 is designed for quick mold replacement, allowing users to switch between different plate sizes and shapes with minimal downtime.

4. How many operators are needed to run the machine?

The machine is semi-automatic with hydraulic control, requiring only one trained operator to monitor and manage the production process.

5. What kind of maintenance does this machine require?

With its reinforced steel frame and durable hydraulic system, the ZPJ-600 only needs routine lubrication and cleaning. We provide a detailed maintenance manual and online support to assist your team.