Efficient thermoforming machine for producing plastic cup lids using PET, PVC, HIPS, or PLA. Supports multi-cavity molds with max forming area of 450×130mm. Integrated forming, punching, and cutting. Ideal for food, beverage, and medical packaging. Compact design, stable output, and customizable for various lid shapes.

Modèle Non :

YK-TF450SNom du produit :

Plastic cup lid forming machineTension :

380V 3P 50HZCapacité de production :

15-35 cycle/minUsage :

to produce plastic lids,medicine/food/daily/electronics/hardwarePort d'expédition :

Shanghai/ningbo portDélai de mise en œuvre :

35daysLester :

1100kg

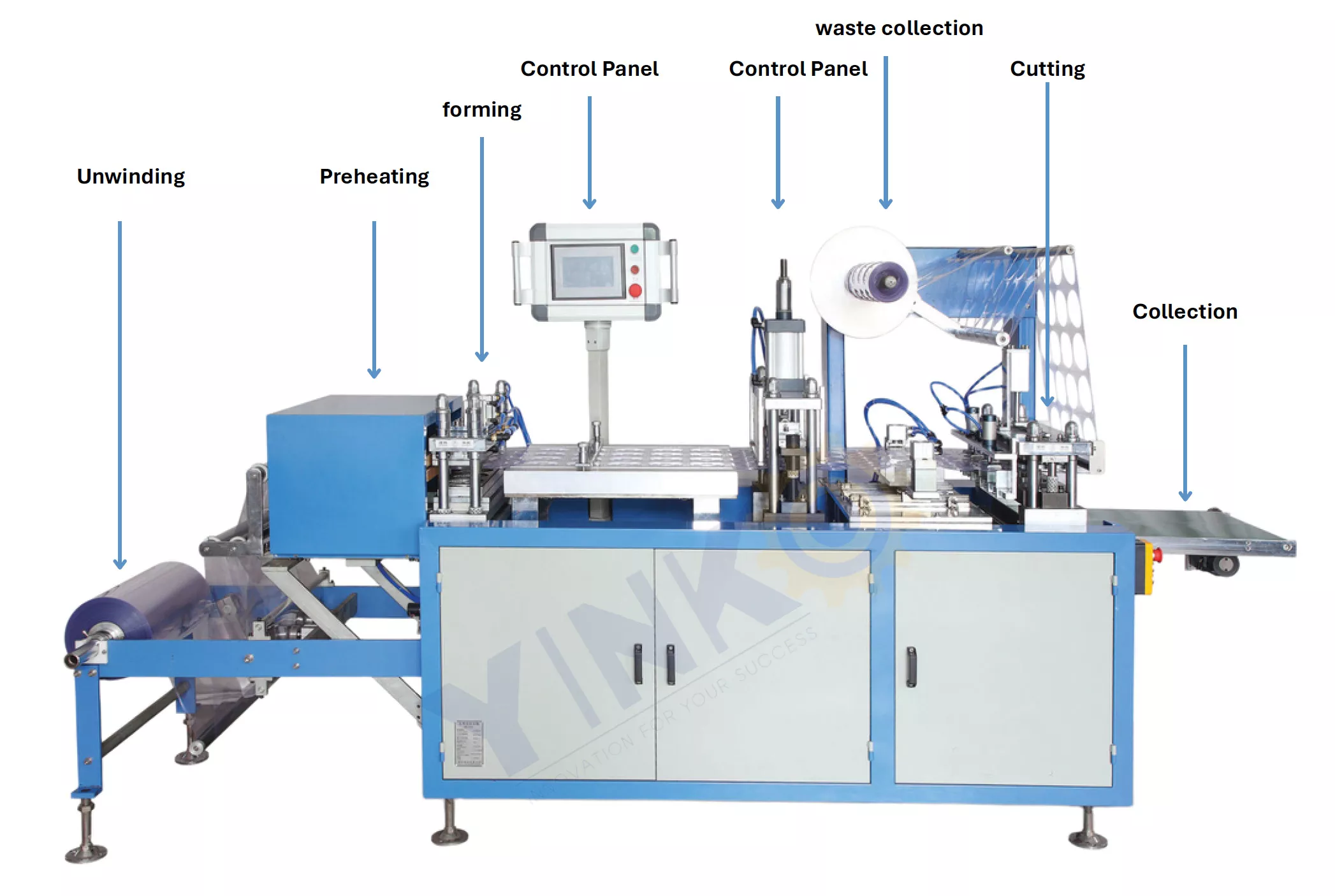

This machine is designed for automatic thermoforming of plastic cup lids, using PVC, PET, HIPS, and PLA sheets.

It is capable of producing a wide range of cup lids, including

Flat lids with straw holes

Dome lids for cold drinks

Sip lids for hot beverages

Medical trays and packaging bases (optional mold design)

Widely used in food & beverage packaging, pharmacy, hardware blister, and daily-use disposable product lines.

✅ Max Forming Area: 450mm (L) × 130mm (W) × 46mm (D)

This large forming size allows multi-cavity mold configurations, ideal for mass production of small-to-medium-sized cup lids or shallow trays.

With 15–35 cycles per minute, the machine delivers stable output for both high-speed and precision-required projects.

This machine integrates

Roll-fed sheet unwinding

Pre-heating and vacuum/pressure forming

Hole punching and edge cutting

Finished lid counting and stacking

|

All processes are synchronized via PLC control with an HMI touchscreen, ensuring high accuracy and minimal material waste.

Material Compatibility: PVC, PET, HIPS, PLA

Forming Speed: 15–35 cycles/min

Power: 4 kW total

Air Requirement: 0.6–1.0 MPa / ≥ 0.6m³/min

Cooling Requirement: 60L/h tap or circulating water

Machine Size: 2600×1100×1700 mm

Machine Weight: 1100 kg

Centralized lubrication system

Adjustable stroke and pressure

Safety-enclosed structure with CE compliance

Easy mold exchange and maintenance

Auto scrap rewinding (optional)

|

Beverage cup lid factories

Fast food packaging manufacturers

Disposable medical tray producers

Electronics or hardware blister suppliers

OEM/ODM packaging solution providers